There are plenty of types of welding. In almost all of these, after welding is necessary to brush in order to get smooth welded surfaces.

For small welds the VIP hand brush is a good choice.

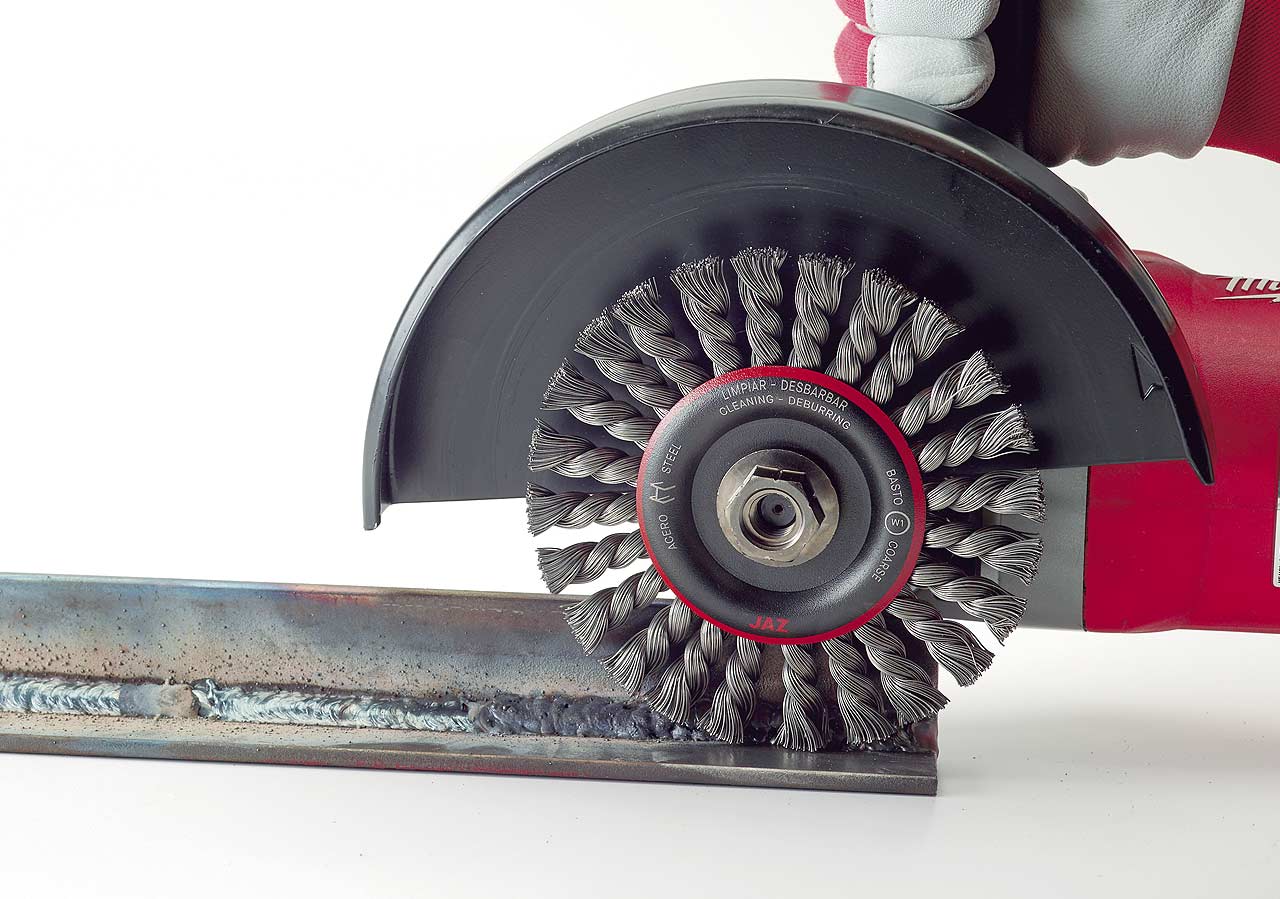

In case of using a power tool to brush, we should choose the most appropriate brush depending on the surface to clean and the rpm of the power tool.

Many of the brushes in our catalogue can be used to smooth a welded surface.

The knotted wire makes the brush to get longer last and higher removal capacity, and the stringer bead wheels of fine face knots (Mod. CPL) are the most appropriate brushes for cleaning the scale on welds.