The effect exerted by the wire ends is like a scrape or a scratch produced by many small blades that remove burrs generated after cutting a tube.

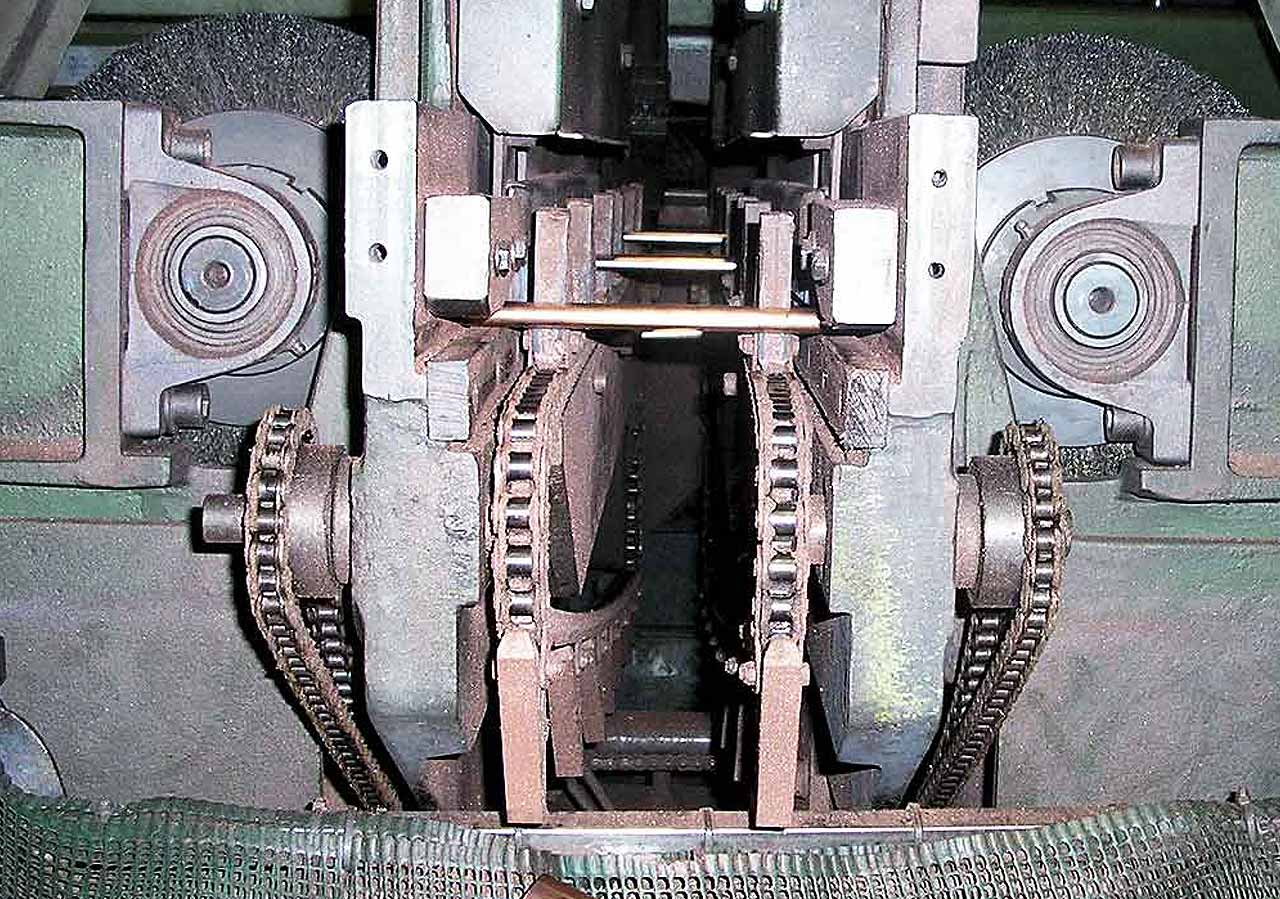

Within the tube deburring, it can be differentiated between the one made in manual and in automatic machinery.

Manual deburring is done on machines with orbital rotation; some popular brands are ROTOMAT, RSA TURNAMAT, SEGURA LLUNEL, TAP and they use brushes of type CT or CCA of high wire density.

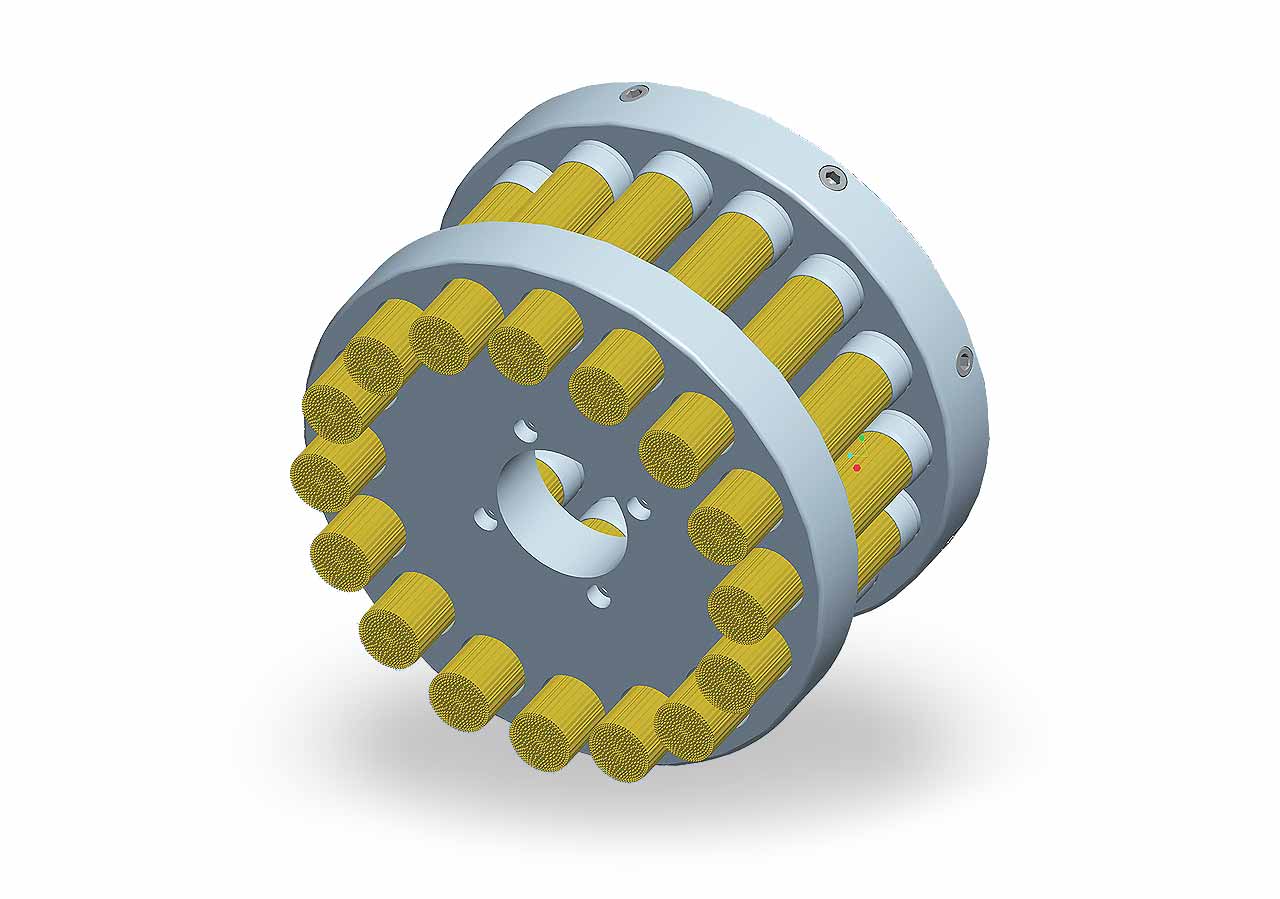

The deburring on automatic machines is done by CUCB blocks which are designed to work on machines from brands like ADIGE, RSA, BEWO, BURMASTER, PEDRAZZOLI, SIMEC etc…

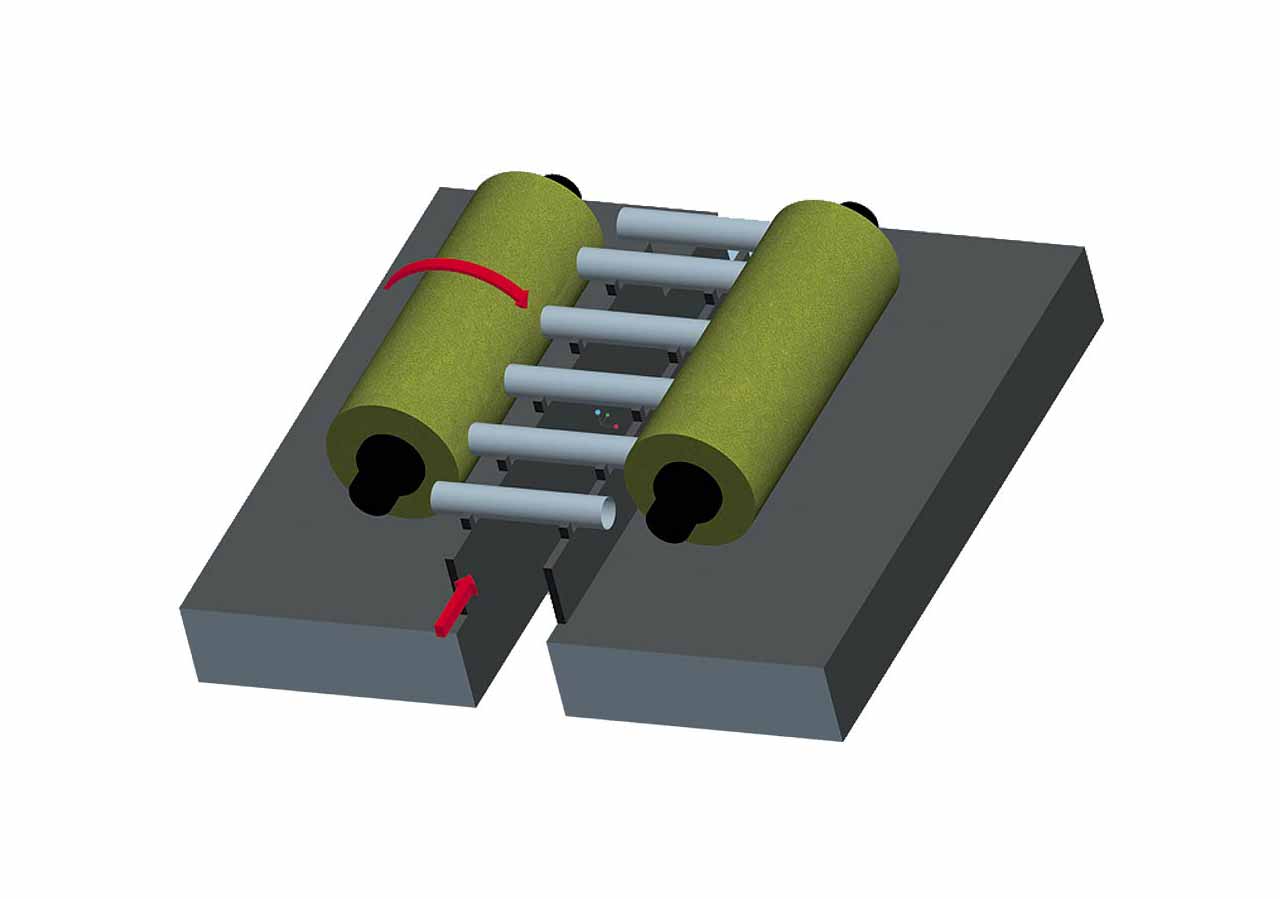

Other type of brushes is the BCSE which is used on machines RASAMAT, also for deburring tube ends.

In any of the cases described above it is important to note that the tube is deburred inside and outside, since both the tube and the brush rotate simultaneously.

This range of brushes can be made with wire of coated steel, stainless steel, abrasive nylon, etc…