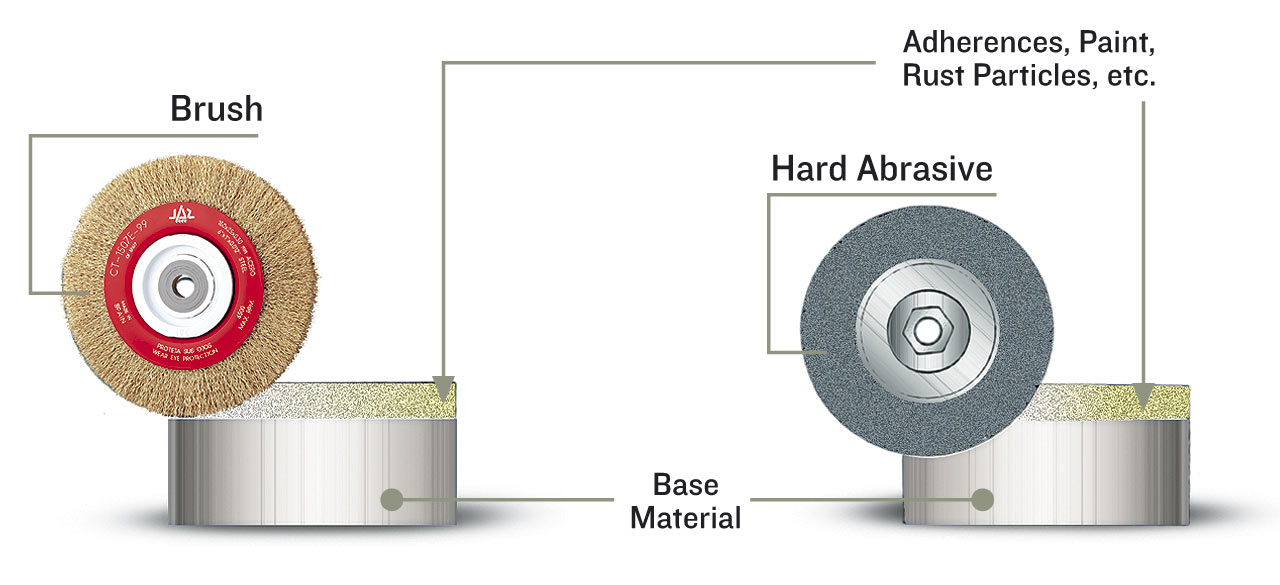

The selection of the right type of brush depends on the type of finishing required (fine or coarse), and the characteristics of the surface to be brushed (stainless steel, carbon steel, wood, etc…).

Besides that, in the case of the brushes fixed in a machine, it is necesary to know the main features of the machine in order to choose the right brush type: