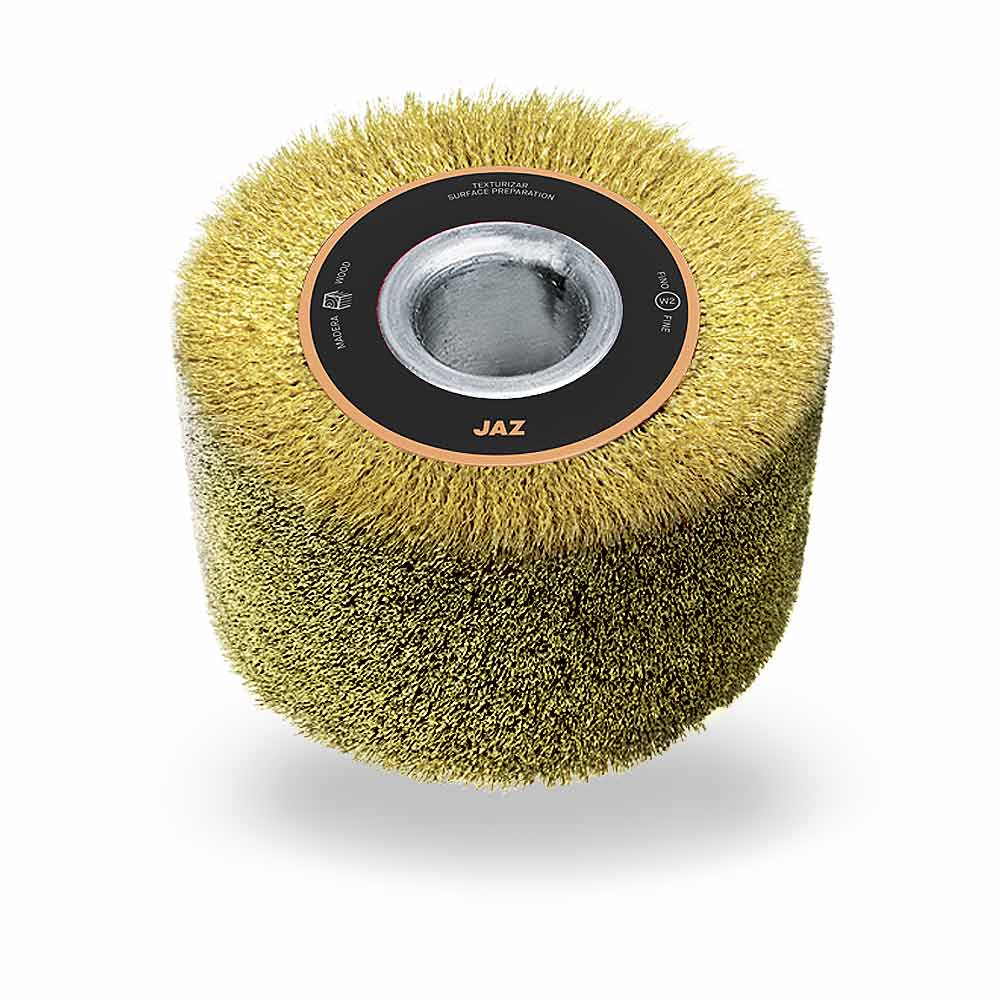

Wood-working brushes for portable machines.

For an antique wood finish for flooring, roofing and furniture pieces, it is best to use a two-step process of steel wire brushes and nylon abrasive brushes.

Steel wires wear the softer parts of the wood and highlight the harder parts. For a finer finishing – removing burrs, sticks and chips resulting from the use of steel wire it is recommended of nylon abrasive brushes.