Nylon Abrasive DIY brushes do not scratch and therefore they are appropriate for cleaning and polishing wood, metallic surfaces, tile, stone, concrete, plastic materials, stainless steel or aluminum.

Measures

| Type | Ø Diameter | Filament | Packing | R.P.M. Max. |

P.C.S. per Box |

|||

|---|---|---|---|---|---|---|---|---|

| mm | " | Color | Grit | Bulk | Display | |||

| Wheel | 75 | 3" | Rojo | 80 | 7500 | 9475 | 4.500 | 12 |

| Azul | 150 | 7501 | 9575 | 4.500 | 12 | |||

| 100 | 4" | Rojo | 80 | 1000 | 9410 | 4.500 | 12 | |

| Azul | 150 | 1001 | 9510 | 4.500 | 12 | |||

| Cup | 50 | 2" | Rojo | 80 | 5000 | 9450 | 4.500 | 12 |

| Azul | 150 | 5001 | 9550 | 4.500 | 12 | |||

| 75 | 3" | Rojo | 80 | 7000 | 9470 | 4.500 | 12 | |

| Azul | 150 | 7001 | 9570 | 4.500 | 12 | |||

| End Brush | 25 | 1" | Rojo | 80 | 2200 | 9422 | 4.500 | 12 |

| Azul | 150 | 2201 | 9522 | 4.500 | 12 | |||

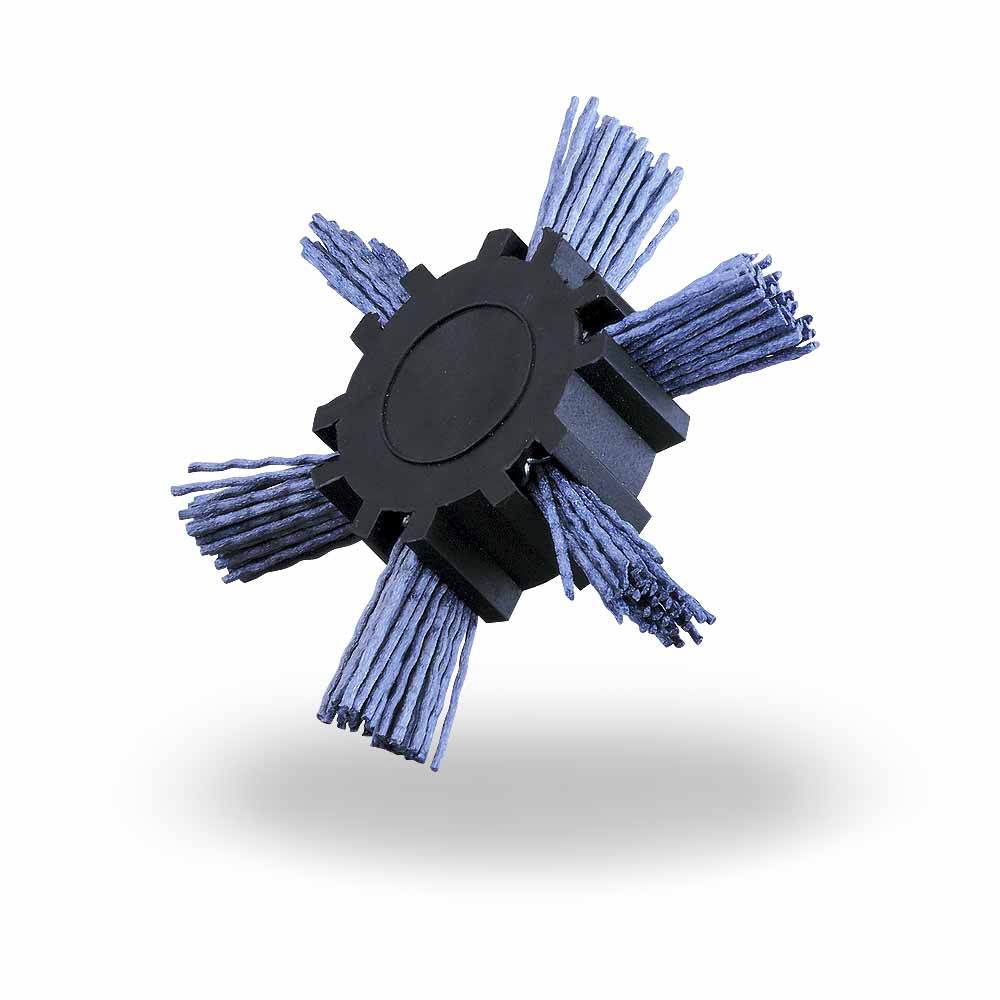

| Flap | 100 | 4" | Rojo | 80 | 1600 | 9416 | 4.500 | 12 |

| Azul | 150 | 1601 | 9516 | 4.500 | 12 | |||

Technical Specifications

Finishing grade

| Abrasive Nylon | Finishing | Grade |

|---|---|---|

| Grit 20|40|60 | Coarse | NA1 |

| Grit 80|100|120 | Medium | NA2 |

| Grit 180|200|300 | Fine | NA3 |

| Grit 400|800|2000 | S. Fine | NA4 |

| Non-Abrasive Fibers | Neutral | SW5 |

Removal rate

| Nylon & Flap brushes | |

|---|---|

| Grit 20|40|60 |

|

| Grit 80|100|120 |

|

| Grit 180|200|300 |

|

| Grit 400|800|2000 |

|

| Non-abrasive Nylon |

|

Flexibility

| DLZ, FLAP, Encapsulated brushes |

|

| Twist knots, Control brushes |

|

| Crimped wire .020 to .012 |

|

| Crimped wire .010 to .004 |

|

| Crimpe wire .003 to .002 Nylon & synthetic fibers |

|

- Brushes made of nylon filaments impregnated with Aluminium Oxide abrasive particles.

- High flexibility without danger of breaking, providing long working life and increased safety.

- Suitable for dry applications only.

- To be used in power drills.

- Red colour nylon brushes (grit 80) produce a coarse finishing; the blue colour ones (grit 150) provide a fine polishing.

Applications

Nylon brushes do not scratch and therefore they are appropriate for cleaning and polishing of:

Additional information

Operating Recommended Speed

Optimum performance is obtained at the recommended working speed 2.500 R.P.M.

Speeds above the recommended ones may smear the workpiece due to heat build-up.