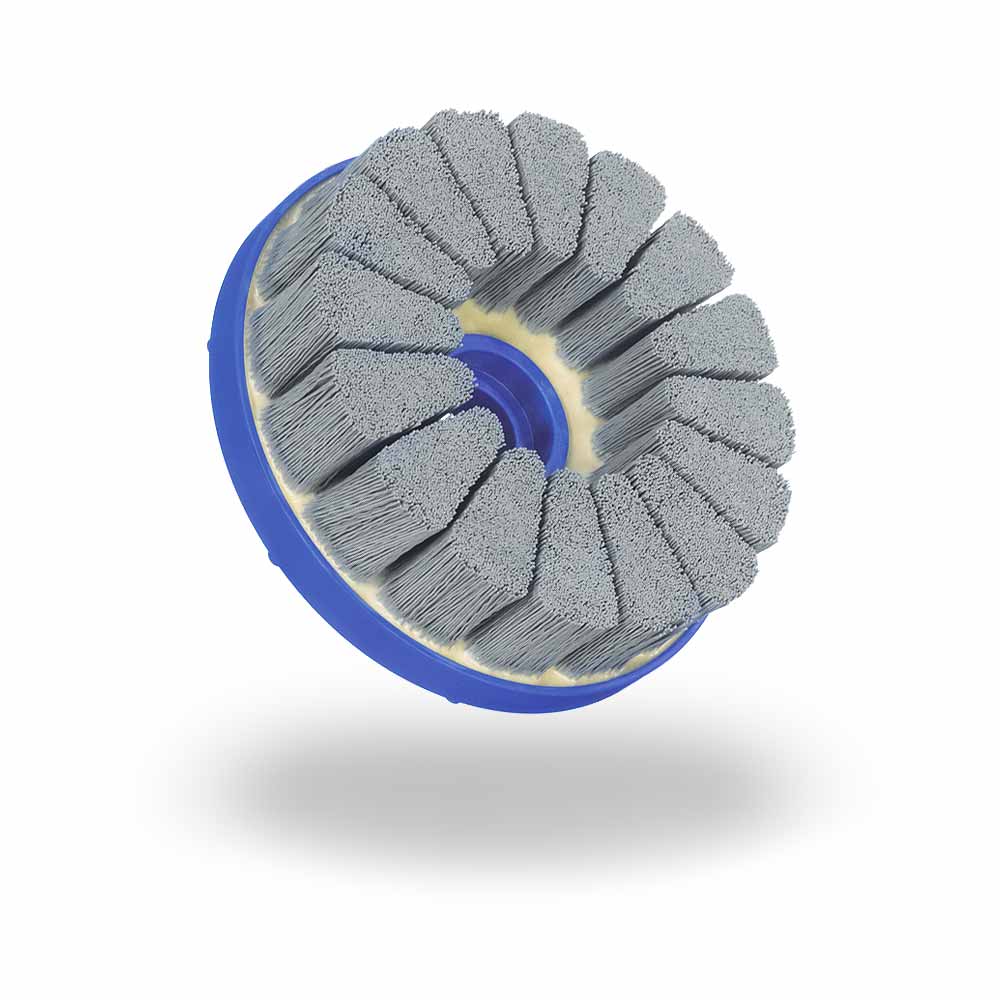

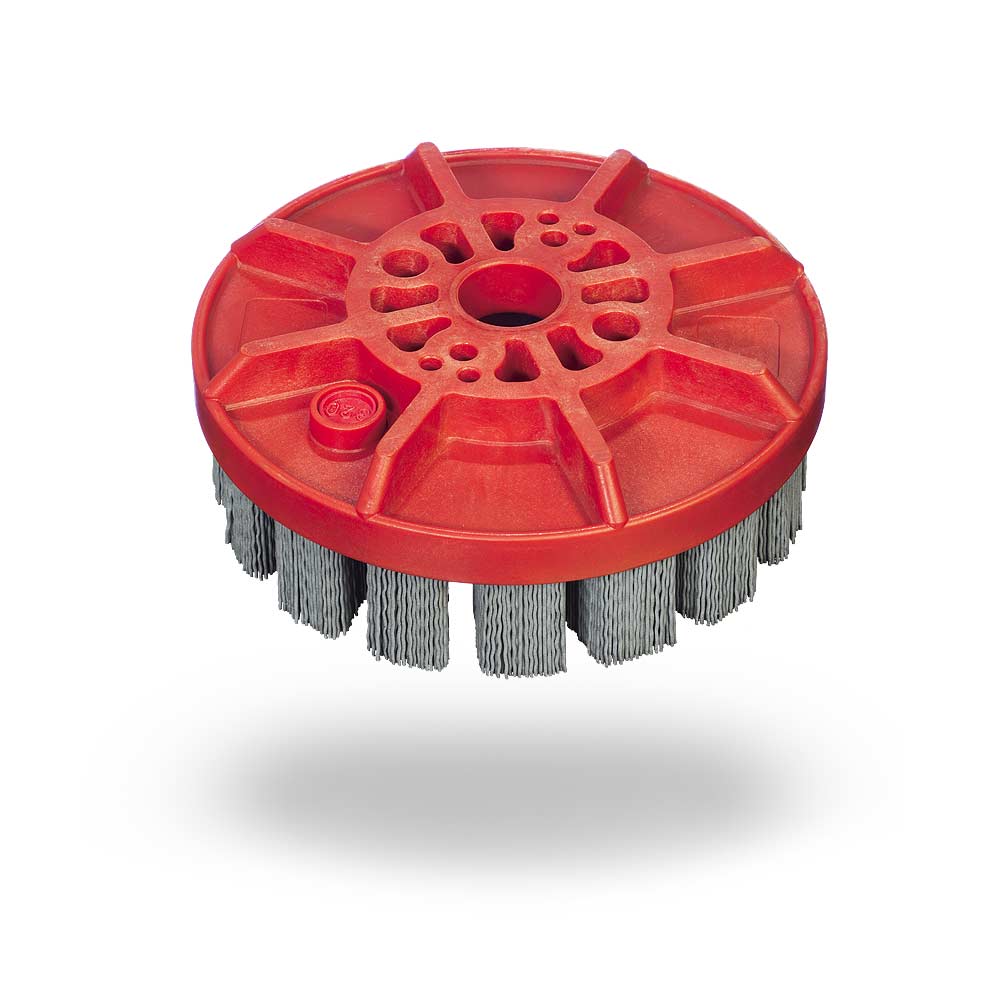

Designed for edge deburring and surface finishing.The position of the filaments allows to enter in small bores or difficult areas access. Suitable for Class I and II burrs. Recommended for deburring

surfaces where all burrs are on the same level.

JAZ “CCM” brushes are mainly composed of nylon filaments impregnated with: Silicon carbide, aluminum oxide, diamond, ceramic coating, etc.

The “CCM” line is designed to be mounted as a tool for use in machining centers, robots, flexible cells, etc.

The “CCM” brushes provide a variety of solutions such as deburring, blending and finishing, rounding of edges, contouring of edges and refinement of surfaces.

Our abrasive filament brushes can be run dry (without a coolant), however applying a “coolant” to the abrasive filaments will improve the finish and performance of the tool.

Industries such as Automotive, Aeronautics, Sintered Metals, etc., where surface finishing is important, can find a solution to many surface finishing problems with JAZ “CCM” brushes.